Introduction:

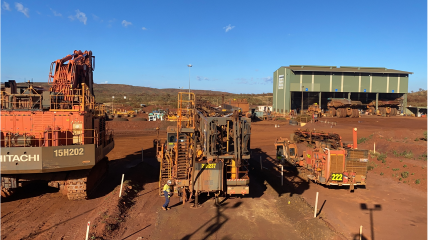

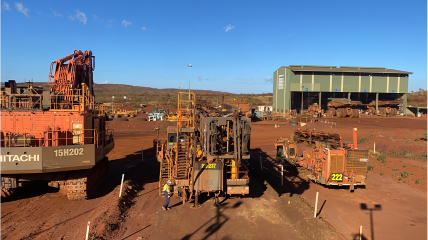

In the dynamic world of mining, the efficiency of material handling is a critical factor that directly influences productivity and profitability. Mining feeding equipment plays a pivotal role in ensuring a smooth and optimized material flow throughout the mining process.

Understanding the Significance of Material Flow Optimization:

Efficient material flow is the backbone of successful mining operations. From ore extraction to processing and transportation, the seamless movement of materials through the various stages of mining is essential for maximizing productivity and minimizing operational costs. Material flow optimization aims to enhance the movement of materials, reduce bottlenecks, and improve overall process efficiency.

The Role of Feeding Equipment in Mining:

Feeding equipment acts as the starting point for material handling in mining operations. Whether it’s loading raw ore onto conveyors or regulating the flow of material into processing equipment, the effectiveness of feeding equipment sets the tone for the entire operation. Well-designed feeding systems contribute to uniform material distribution and prevent congestion, ensuring a steady and controlled flow.

Types of Effective Mining Feeding Equipment:

a. Apron Feeders:

Apron feeders are robust and reliable, capable of handling heavy-duty materials. They are ideal for applications where a controlled and even flow of material is crucial. Apron feeders prevent spillage and ensure a consistent feed rate, optimizing downstream processes.

b. Vibrating Grizzly Feeders:

Vibrating grizzly feeders use vibration to convey material forward. These feeders excel in separating fines from the primary material flow, preventing unnecessary wear on downstream equipment. Their adjustable settings allow operators to control the size of the material passing through.

c. Belt Feeders:

Belt feeders are versatile and commonly used for handling bulk materials. They can be customized to suit specific applications and are effective in controlling the rate of material discharge. Belt feeders contribute to a smooth and regulated flow of material onto conveyors or into processing equipment.

Benefits of Effective Feeding Equipment:

a. Reduced Downtime:

Well-designed feeding equipment minimizes interruptions in material flow, reducing downtime and increasing overall operational efficiency.

b. Improved Equipment Longevity:

Consistent and controlled material flow prevents overloading and excessive wear on downstream equipment, contributing to extended equipment lifespan.

c. Enhanced Safety:

Effective feeding equipment helps maintain a safe working environment by preventing material spillage, minimizing the risk of accidents and injuries.

d. Optimized Energy Consumption:

By ensuring a steady and controlled flow, feeding equipment helps optimize energy usage in mining operations, contributing to cost savings.

Implementing Material Flow Optimization Strategies:

a. Regular Maintenance:

Schedule routine maintenance for feeding equipment to address wear and tear, ensuring optimal performance.

b. Monitoring and Adjusting:

Use real-time monitoring systems to assess material flow and make adjustments as needed to prevent bottlenecks or irregularities.

c. Operator Training:

Train equipment operators to understand the importance of material flow optimization and how to operate feeding equipment effectively.

Effective mining feeding equipment is not just a necessity; it’s a strategic investment in the success of mining operations. By prioritizing material flow optimization through well-designed and well-maintained feeding equipment, mining companies can streamline processes, reduce operational costs, and enhance overall productivity in this crucial industry.

Working Time: Mon-Sat: 9 AM – 5 PM

Working Time: Mon-Sat: 9 AM – 5 PM Email:

Email:

Post a Comment